The hottest passion for customers

We have grown along with our customers with excellent quality and strict delivery schedule. We have been researching, developing and producing heating systems for specialized in engineering industry such as heavy industrial plant, automobile, heavy chemical, plastics, new material, shipbuilding.

We will do our best to design, produce and construct the entire heating system during your production process. Our heating system can be applied to heavy chemical plant and power plant, and it designs, manufactures and installs fluid heating system, explosion-proof heating heater, PRE-HEATER for ship and hot air.

In order to satisfy the expectation of our customers, we promise that all of our executives and employees will do their best.

CEO You-Gi Cho

Blazing fire! burning over a thousand years...

Business Areas

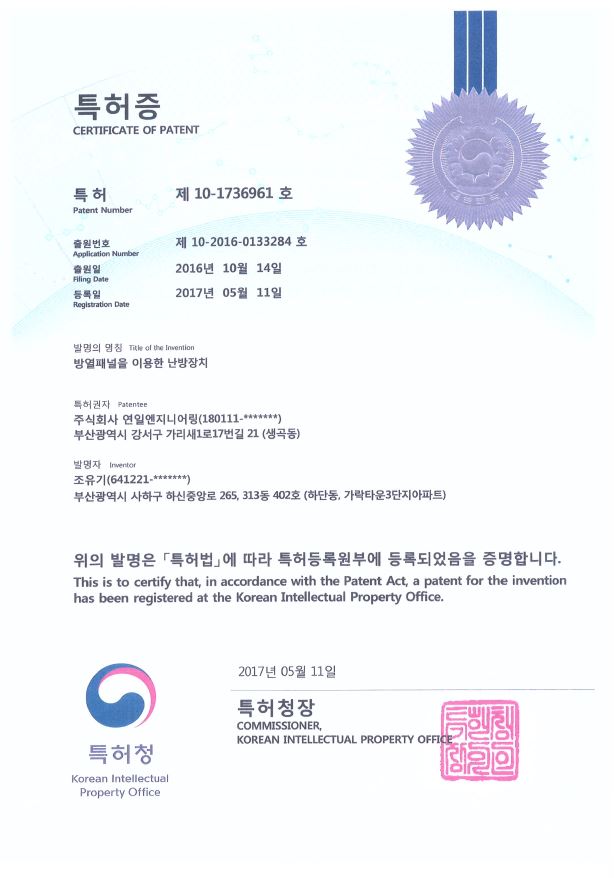

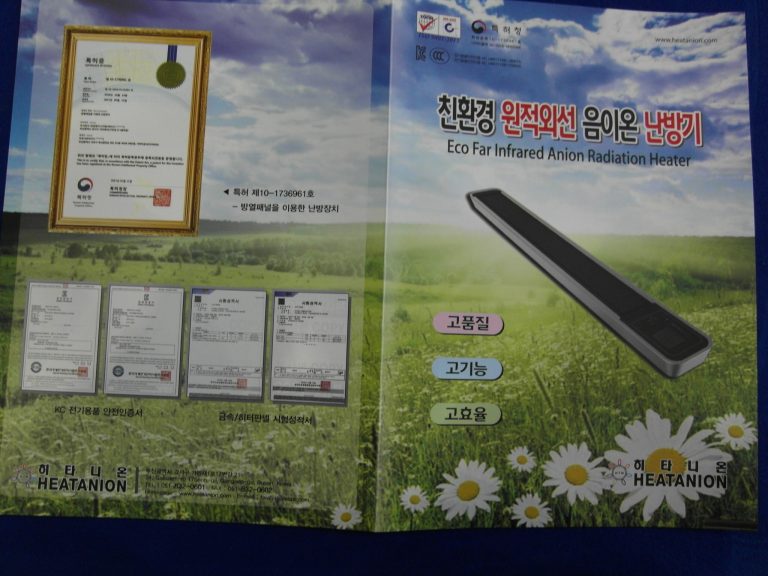

Far infrared heater HEATANION

- Painting booth drying system (Automobile / Aircraft / Ship / Machine etc.)

- Wood booth drying system (packaging / furniture etc.)

- Green house heating system (plant cultivation, insect culture, etc.)

- Living space heating system (office, coffee shop, flower shop, etc)

- Power : 1000W, 1200W, 1600W, 2000W, 2200W, 3000W

- Boltage : 220V

- Size(W X L) : 180 X 800, 180 X 1200, 180 X 1400

- 300 X 800, 300 X 1200, 300 X 1400

- 400 X 1200, 600 X 600

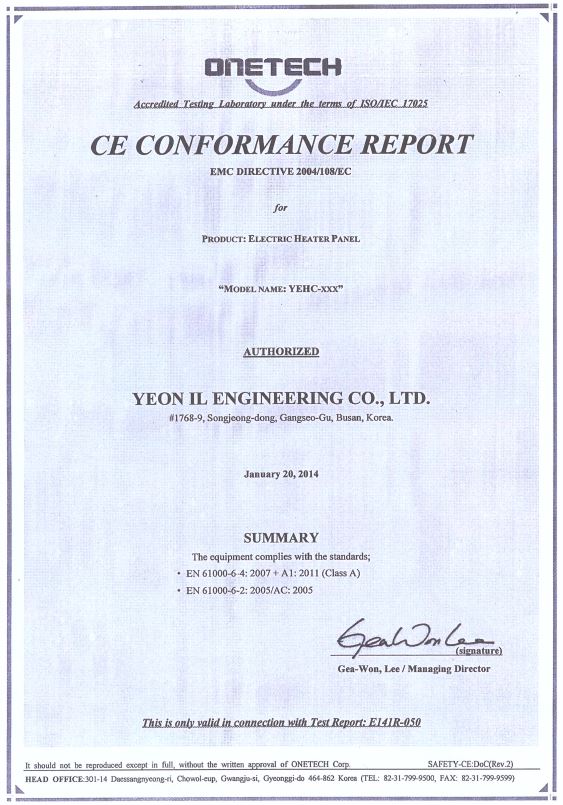

Industrial electric heaters

- Explosion-proof Heaters (IEC-EX)

- Input heater, heat wire (Kantal)

- Plating heater

- Electric knife

- Temperature Sensor

- PLC control panel

- Temperature control system

- Flow and pressure control system

Thermal application system

- Drying furnace

- Painting hot air dryer

- Automobile wire warmer (softener)

- Gas Burner Type Drying Furnace

- Heat treatment furnace

- Hot air dryer

- Painting booth drying device (Automobile / Aircraft / Ship / Machine etc.)

ANTI-ICING & DE-ICING

- Walkway

- Stair

- Louver

- Fire Hose Box

- Handrail

- Helidack

- Piping

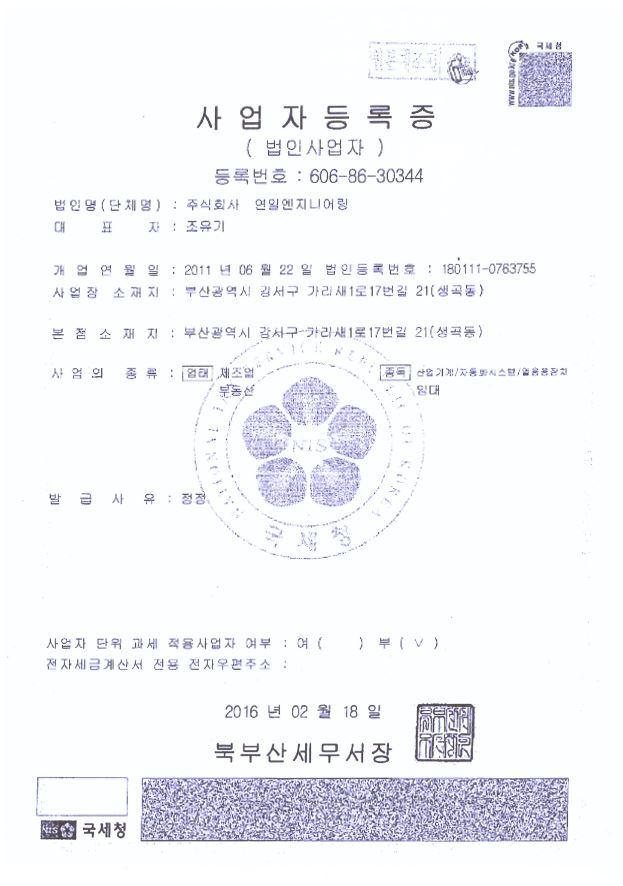

Company History

- ‘2017 Obtained explosion-proof heater certification for shipbuilding / heavy industry (IEC EX in progress)

- ‘2017 Acquired product certification of far infrared ray heater for painting booth (KCS in progress)

- ‘2016 Developed far infrared ray explosion heater for paint booth

- ‘2015 Developed far-infrared heating heater for residential facilities

- ‘2012 Established research department

- ‘2012 Developed new product development condition-based ANIT-ICING / DE-ICING

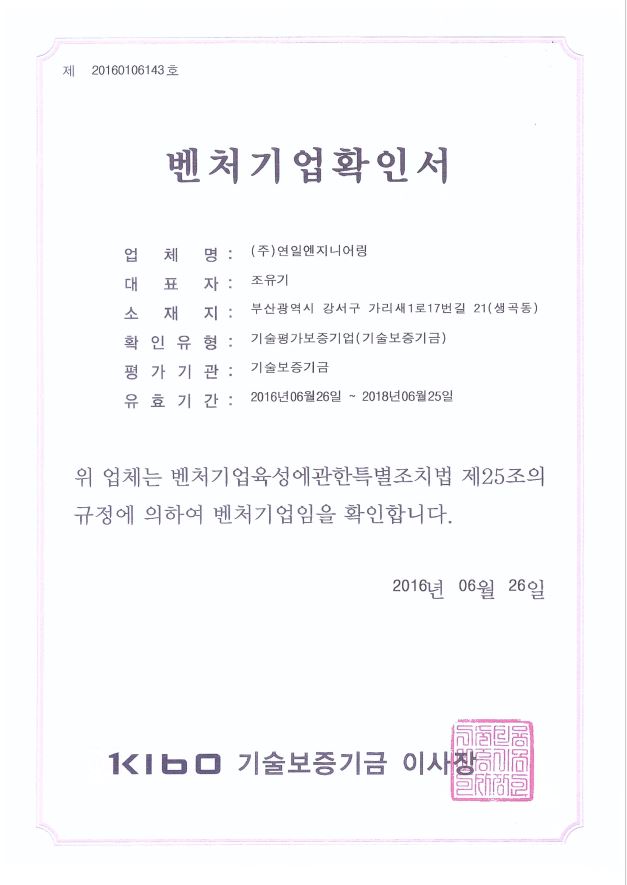

- ‘2012 Registered as a venture company

- ‘2011 Incorporated into Yeonil Engineering Co., Ltd.

- ‘2008 Obtained explosion-proof heater certification

- ‘1997 Established company

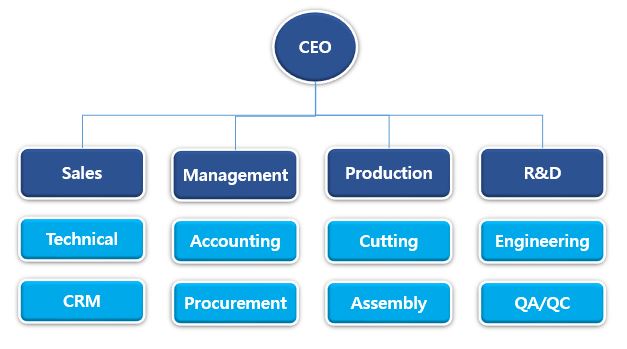

Organization

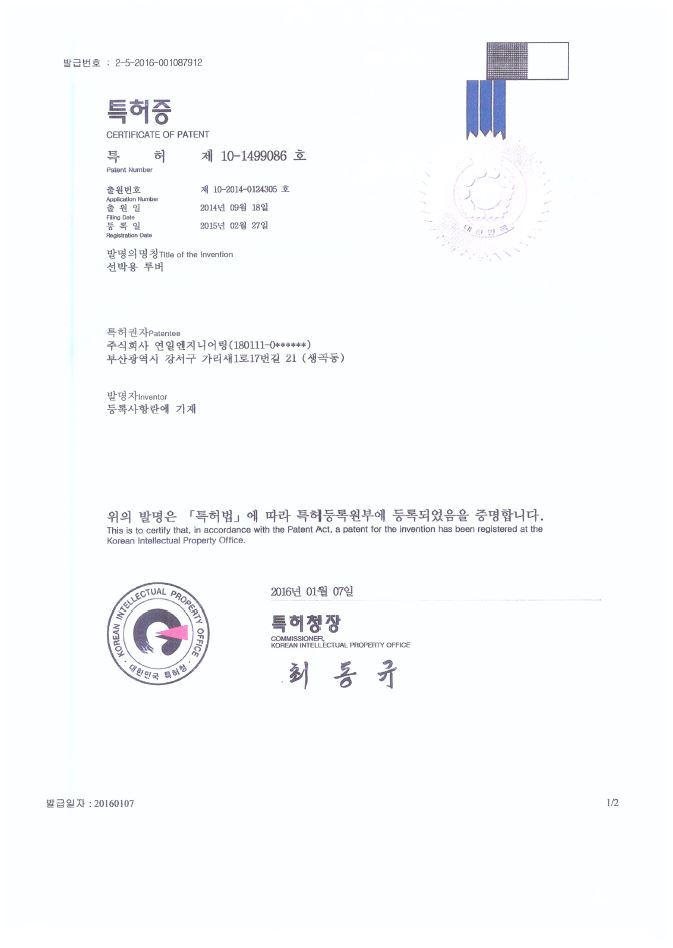

Certificate

Clients

Business performance

Photovoltaic power generation equipment

- Capacity : 25KW

- Client : Gangseo-gu Office

- Place : Resident center

- Delivery : 2016.02

Photovoltaic power generation equipment

- Capacity : 100KW

- Client : Gangseo-gu Office

- Place : Indoor gym

- Delivery : 2015.10

Glycol Water Heater

- Capacity : 440V/110KW

- Client : Donghwa Entec CO,. LTD

- Place : DSME

- Project : H2407

- Delivery : 2014.12

MGE L.O Purifier Heater(Drillship)

- Capacity : 440V/52KW

- Client : Donghwa Entec CO,. LTD

- Place : DSME

- Project : H3618

- Delivery : 2014.02

Movable paint fan

- Clent : Hundai Rotem CO,. LTD

- Place : Hundai Rotem CO,. LTD

Foam chamber facility

- Capacity : 372,000Kcal

- Client : FAMOTER

- Place : Samsung Electronics Co., Ltd

- Delivery : 2011.12

Hot Wind Fin Heater

- Capacity : 480V/10KW

- Client : Doosan Engine Co., Ltd.

- Place : Power plant

- Project : Singori 3/4 AAC DG

- Delivery : 2011.09

HT Water Electric Heater

- Capacity : 480V/45KW

- Client : Doosan Engine Co., Ltd.

- Place : Power plant

- Project : Singori 3/4 AAC DG

- Delivery : 2011.09

HT Water Electric Heater

- Capacity : 480V/45KW

- Client : KPHE CO,. LTD.

- Place : Power plant

- Project : Yeongwol power plant AAC DG

- Delevery : 2011.09

ANTI-ICING (Louver Heater)

- Capacity : 440V

- Client : Sangrim CO,. LTD.

- Place : SHI

- Project : SH1940

- Delivery : 2011.06

Steam Furnace

- Capacity : 100,000Kcal

- Client : Hanil boiler CO,. LTD.

- Place : Hanil boiler CO,. LTD.

Tire Gas Drying Furnace

- Capacity : 350,000Kcal

- Client : Hankook engineering CO,. LTD.

- Place : Hyundai motor CO,. LTD.

Seat Drying Furnace

- Capacity : 380V/220KW

- Client : Dong-a E&G

- Place : Dong-a E&G

Hot air dryer for thread

- Capacity : 380V/10KW

- Client : MOT

- Place : KAL

Gas type heat treatment furnace

- Capacity : 450,000Kcal

- Client : Samgeon Seagi Co., Ltd.

- Place : Samgeon Seagi Co., Ltd.

Explosion-proof Top-loading heater

- Capacity : 380V/40KW

- Client : UNS CO,. LTD.

- Place : Daesung Industrial Gas CO,. LTD.

- Delivery : 2010.03